Composite of a life: R. Byron Pipes

This article was originally published on Medium.com, Purdue College of Engineering. We repost this interview here with Dr. Pipes' permission.

R. Byron Pipes, NAE, is the John Bray Distinguished Professor of Engineering and executive director of the Composites Manufacturing & Simulation Center (CMSC) at Purdue. Purdue Engineering Review sat down with him for a talk about his life in engineering.

Why are you so keen on composite materials? What is the value and interest you see there?

I have always advised my students upon graduation to look for a position where significant and continued learning must occur, where exciting new ideas are being developed. I took my own advice in 1969 when I joined the Composite Structures Group at a major aerospace conglomerate, General Dynamics. Composed largely of doctoral graduates in engineering, the team was challenged by the U.S. Air Force to develop advanced composites to provide weight savings for fuel efficiency and performance gains for military aircraft. In a few short years, all future aircraft — commercial and defense — would contain components constructed of composite materials, and, indeed, stealth technology would demand that the aircraft be made entirely of composites.

What was your youth like? What kindled your love of engineering?

Engineering and creativity have always been linked in my mind, and, early on, my interests were in architecture, where “form follows function” while simultaneously creating beauty. Perhaps the earliest manifestation of my interest in engineering occurred when I saw a sign in a General Motors dealership advertising the Soap Box Derby race for boys aged 12–15. The race required the boy (girls joined the race in the 1970s) to build his own car while following a few specific directions and goals. The Soap Box Derby organization supplied a steering wheel, four wheels and two axels (purchase price $25, circa 1953), but the rest was up to the boy. My father helped me access a large-scale band saw to make the curved cuts required for the aerodynamic shape of the car. Our neighborhood appliance store owner agreed to supply the $25 in exchange for painting the “Brown Bros. Appliances” name on the side of the car. Constructed largely of plywood, the car was designed as a ribbed structure with a thin skin of ¼-inch plywood and sheet metal. It was painted dark green with the tiger shark of the Flying Tigers P-52 on the nose of the car for aesthetic advantage. The learning experience in creating an engineered system to meet a set of specifications revealed just what technical creativity could be, and I was hooked!

Twelve-year-old R. Byron Pipes with his Soap Box Derby entry

Can you say something about the intellectual environment at Purdue’s College of Engineering?

The College of Engineering at Purdue is the lifeblood of the institution. Of course, its sister colleges are important to the university in addressing the diversity of the global, national and state issues essential to the mission of a land grant university. The College of Engineering is a rich and intellectually diverse assembly of scholars who demonstrate allegiance to their individual discipline communities while at the same time supporting the West Lafayette campus and community. Unlike universities located in or near large cities, Purdue is surrounded by agricultural enterprise and open space. Its recent development of adjacent land to the “live-work-play” model in the Discovery Park District at Purdue is bringing business enterprise and new human talent to the region.

What is your philosophy of teaching?

My opinion now is that the American university model of the co-location of teaching and research is the right approach. No doubt there always will be a creative tension in a person who loves the combined life of teacher and researcher, because the two activities compete for attention and academic institutions can value one over the other. Still, I believe that engaging students in learning that involves both knowledge conveyance and discovery can provide an exciting and effective environment. The “Google Age” has made information a commodity, and the modern faculty member is challenged to decide just what to teach — not only because information creation is accelerating, but also because we wish to convey knowledge and not merely information. Just how one derives from the other continues to challenge the profession. Finally, I have discovered late in my career that it is the passion for the subject demonstrated in both the classroom and the laboratory that attracts students to learning, and I make every effort to show why I am so excited about learning more each day.

You’ve often spoken about the democratization of digital transformation. What do you mean?

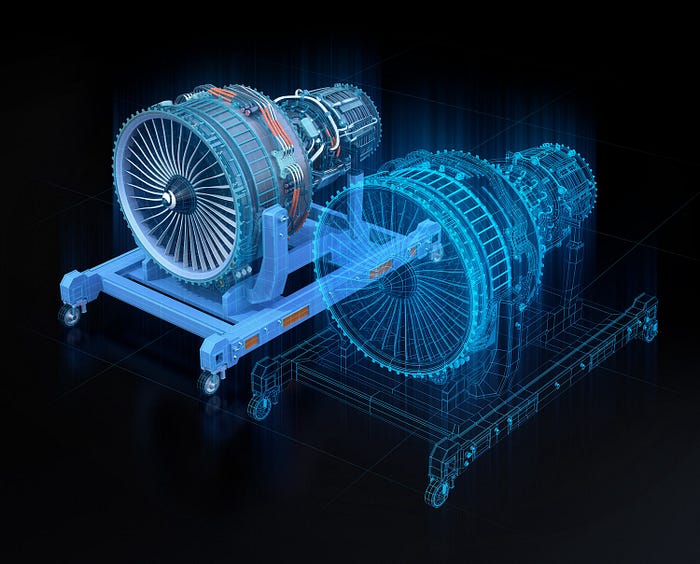

Democracy in this context means that everyone in an industrial supply chain would get equal access to the tools of modern digital transformation. This would benefit not only the supply chain company but also the larger manufacturer, as small firms would then have the wherewithal to innovate for performance and economic gains that would flow through the entire supply chain. Right now, the benefits to the “haves” greatly disadvantage the “have-nots.” Using tools like model-based systems engineering and the digital twin, the “haves” can explore a range of manufacturing materials and processes upfront, digitally; more alternatives can be considered and risk can be reduced before committing to expensive physical assets. Small and medium-sized businesses are the “have-nots,” relying on trial and error, because simulation platforms and supporting personnel are too pricey. A national program that addresses the “haves and have-nots” situation is clearly in the interest of our nation and its future as a global industrial power.

Where are we headed with simulation, digital twin, additive manufacturing, and the like?

Engineering is undergoing rapid digital transformation. The digital systems model and the digital twin enable partners to integrate their decision making in a shared process that speeds product development and ensures decision traceability over the product life. The digital twin of the manufacturing process is a primary focus right now, because of its ability to both capture unique manufacturing details and help assess changes in product performance and operational and maintenance needs across the product lifecycle. Additive manufacturing will soon provide individualized products at manufacturing costs now only achieved by large-scale, automated production. Replacement parts will be produced on site, without the need to stock inventory. A whole new machine tool industry is emerging. Major corporations have already installed systems that demonstrate a dramatic positive impact on both cost and time-to-build for critical industrial components, such as very large production molds, tooling and fixtures. The future potential and benefits of this emerging technology could be highly significant to creating and maintaining a competitive advantage for major U.S. industries worldwide.

Purdue’s Composites Manufacturing & Simulation Center (CMSC), where the Thermwood Large Scale Additive Manufacturing laboratory, pictured, produced the Las Vegas Raiders’ Al Davis Memorial Torch — the world’s tallest 3D-printed structure. (Purdue University photo)

Why is collaboration among academic, industrial and governmental bodies so vital?

The roles of academia, industry and government have been changing in the past several decades, and collaborations among the three segments have been growing significantly. This trend has occurred because of the enormous growth in research in academia and a corresponding decline in internal industrial research. Government has recognized this change and has supported programs aimed at encouraging academia-industry partnerships. A major transformation has taken place wherein all or almost all industrial research is now supported either directly or indirectly by government. This shift has begun to change the relationship between academia and industry, as the two may be partners in one relationship and competitors in another. Government has also become less patient in its investments in research as society demands more rapid conversion of research results into enterprise prosperity.

Any words of advice to young people with an interest in engineering?

Students who question me about engineering always get a story about the creative life that engineers live. I tell them that if they want to work at the intersection of science and its application for the creation of prosperity, both for themselves and for society, engineering is a great choice. It certainly has been for me. I also relate that life is full of opportunities, and they may state that success is a matter of good luck. I immediately agree, with the proviso that good luck is the intersection of opportunity and preparation. As to opportunity, it falls like rain throughout one’s life and is never controlled by the individual, but preparation is clearly in their hands. So, I encourage them to get prepared now because the opportunities are coming and those who are prepared will accept them and achieve success.

Any hobbies, interests in your “spare” time?

My bride of almost 60 years, Ruth Ellen, is an avid horticulturist and keyboard musician. Thus, duties as yard gardener and music supporter have filled my extra time with beauty and hard work, including frequent planting and replanting of ornamental shrubs and flowers to turn our small piece of land in Lafayette into a well-groomed garden. Ruth Ellen served as a church organist for more than 25 years. While in England one summer, we visited all 50 chapels in Cambridge to hear concerts or Evensong services while listening to a different organ in each one. I live in a beautiful home among the images and remembrances of my presidency of Rensselaer Polytechnic Institute, including a photograph of the ECAC Championship Rensselaer hockey team of 1995 signed by all the team members, as well as a game football with “RPI 30 — Union 7” painted on one side and “President Pipes” on the other. It was a victory never before achieved, and, yes, I am a sports fan! Finally, Boilermaker sports teams have kept my support over the past 18 years by the combination of passion and integrity of the Purdue athletes. Boiler Up!

Related Links

Composites Manufacturing & Simulation Center (CMSC)

Purdue Engineering Review: ‘Engineering in the digital age’

Purdue Engineering Review: ‘Virtual twins — intersection of the real and digital worlds’